The Deuce & Humpty Dumpty

So, I stand over two sets of transmissions and transfer cases, one each from the Deuce and Humpty Dumpty, the donor jeep. From the 10 foot view, they look identical. Both T18 4 speed transmissions mated to a Dana 20 transfer case. Yeah, as if I am that lucky.

Checking the gears, the Deuce has the much more favorable low first gear, 6.32 vs 4.02. It also has the shorter input shaft, which is better for the short jeeps, but it also doesn’t match up with Humpty’s longer shaft. And the transfer case on the Deuce is also a 2.46 to 1 as opposed to Humpty’s 2 to 1. Rotating both by hand, the Deuce definitely has something wrong with the bearings. Lots of grit and lumps. Whereas the donor parts rotate smoothly.

I am considering throwing the whole Humpty Dumpty setup from the bell housing to the driveshafts into the Deuce just to get it rolling. Then I open the cases up.

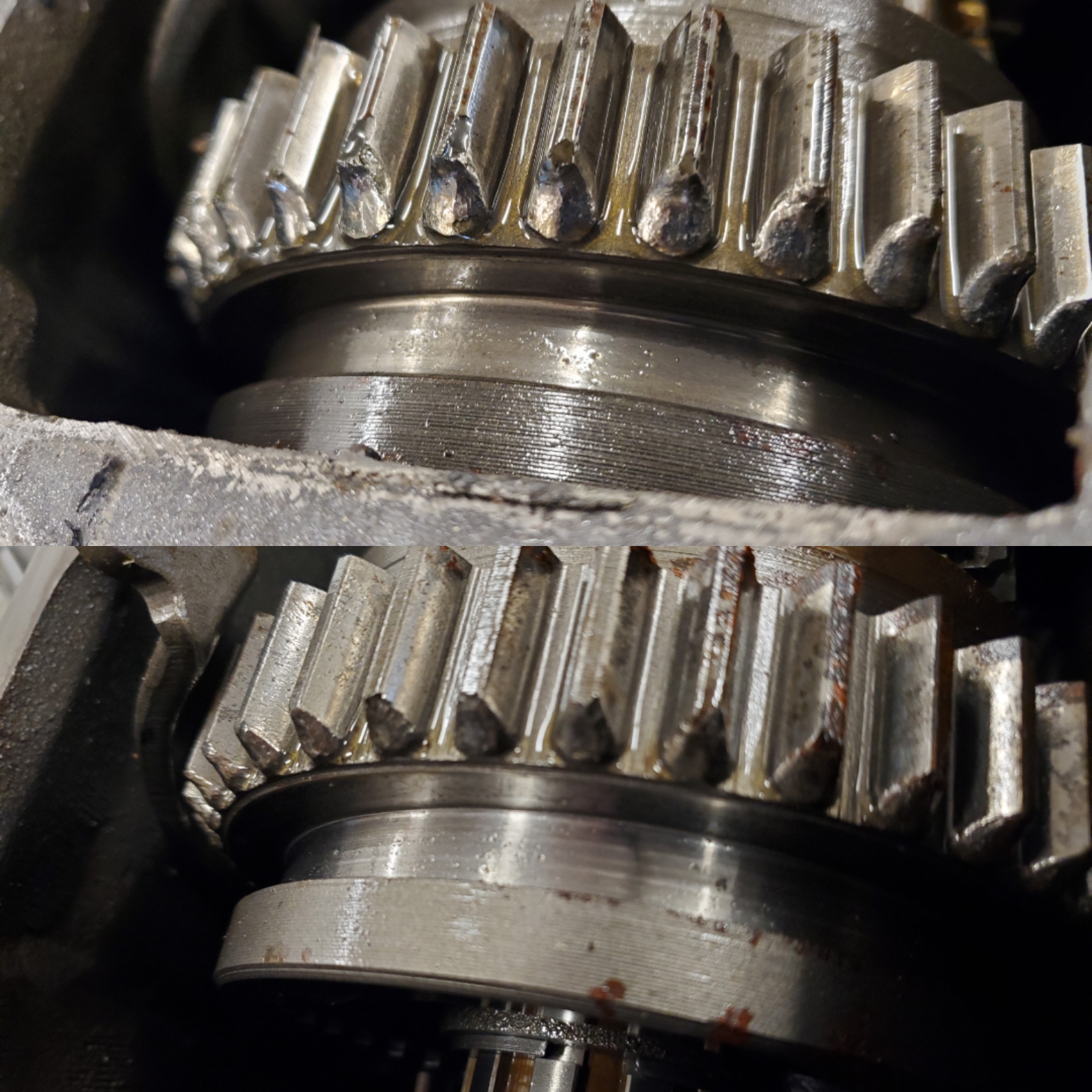

The Deuce had a couple of bits of teeth at the bottom, but only a couple of spots where is gears are crunched. Humpty’s however, only has metal shavings in the oil…but the first/second gear sleeve is badly worn. Badly is a serious understatement. It appears that someone just didn’t like waiting to come to a complete stop before attempting to shift into reverse. The entire way around the gear is severely mangled. The reverse gear way down in the case does not look any better. That could not have been a good sound. At all.

So, the Deuce has bad bearings and Humpty has bad gears.

Well shit. My thoughts of Frankensteining one good transmission out of two gear sets are over. I decide to just tear into the Deuce’s parts are rebuild what I need. Later, I can rebuild the Humpty parts for a spare trans. It’ll be much easy that way. I think.

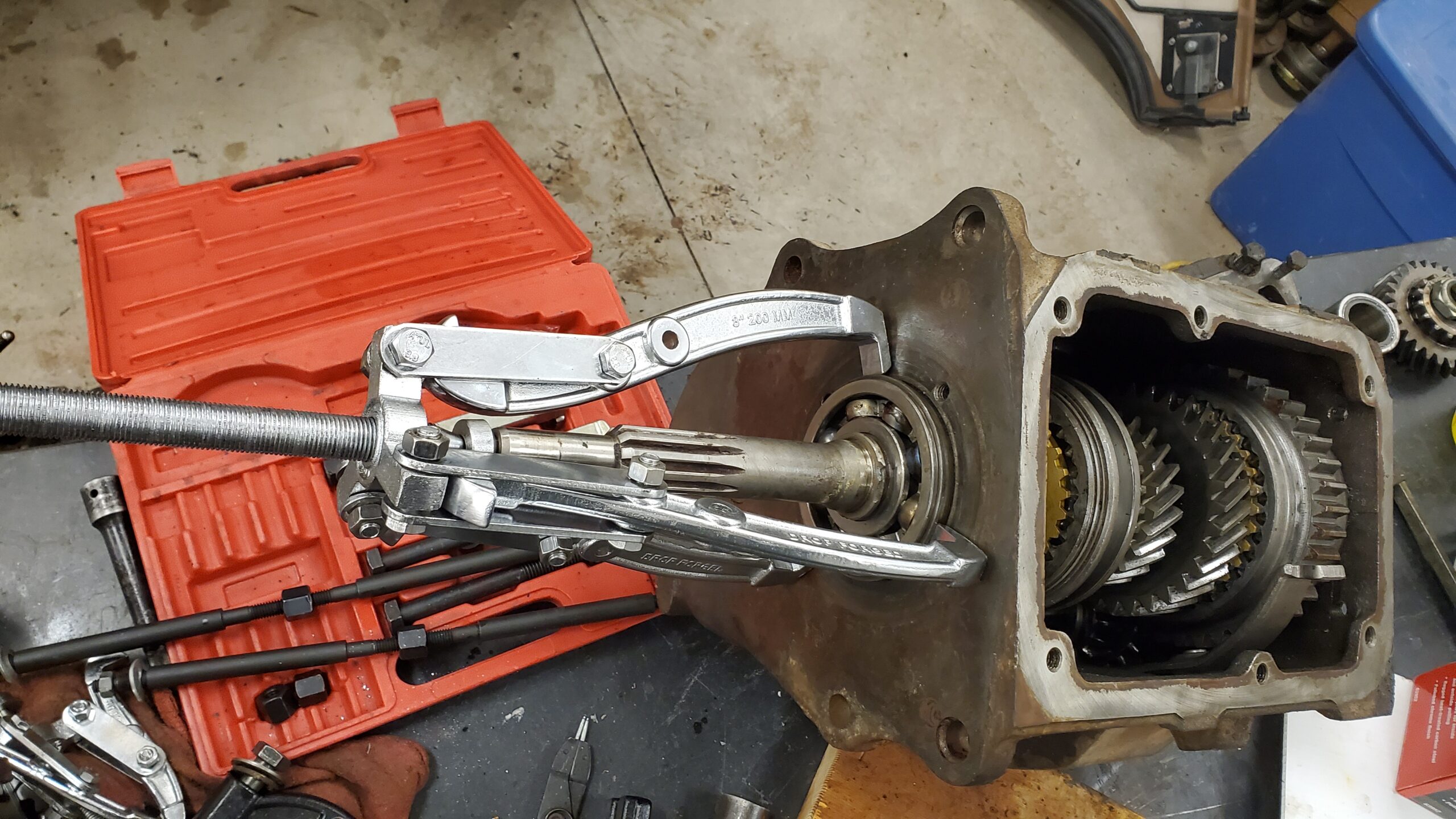

The first obstacle was getting the front bearing off. My gear puller is just not quite long enough to be used with the supplied threaded rods. Like 1/2 inch too short. I can use it if I double up the rods, but then it is almost twice as long as intended. And sure enough, it just leans over just as it starts to tighten up.

I still try it like 12 times.

I even leave them tentioned overnight after drowning the bearing in penetrating oil.

That was using the flat clamshell design puller with two puller rods. I look through my 3 jaw pullers, but they are all too short. I tried to extend the pivot arms on the pullers, but i didn’t have enough scrap metal to make the length I needed. And the two piece arms I attempted to make just failed hilariously.

Off to my favorite cheap tool store and they have a set that is long enough. Of course, the jaws are too deep to fit under the snap ring on the bearing. Take them over to the grinder and after three tries, I get them to fit.

I pull tension on the bearing, but it still just sits there flipping me off. I blast it with more penetrating oil. I torch it with heat. Nothing. So, again, I leave it tensioned all night.

The next morning, I again hit it with the torch and then hit it with the hammer. After 20 minutes, I’m about to give up, but then I notice that there is some minor movement to the bearing. Or maybe it’s just wishful thinking. More heat, more hammering. Oh YES! Definite movement. Crank, hammer, crank hammer. It starts out with sub-millimeter movements, but gains more and more slowly. The last little bit comes out with only cranking the puller.

Three days. There damn days. But I got it off. Sweet. It brings me back from the edge of insanity.

Next up is to remove the reverse lever from the side of the case so you can actually lift the gears out. Knock out the drift pin that hold the pivot in the case and you’re done. Simple, right?

I start knocking the pin through. It gets halfway through and gets stubborn. Slowly starts needing more and more effort to move it. About 3/4 of the way though, it stops. Wtf?

I take a break. I come back the next day and start again. No movement. Frustration. Then the hardened steel punch I’m using snaps off in the hole. Aw, come on!

Maybe I can grab the end of the pin and pull it out. Nope, it just snaps off. Grr. Maybe I can tap the tip of punch out by knocking the pin the opposite way through the hole. This time, just as I’m thinking I’m making progress, the tip of the punch snaps off again.

So now I have two hardened bit of punches stuck in either end of a case with no way to get a purchase on either one. How the hell am I going to get this out?

Drilling it seems to be my only option, but I don’t have the correct bits for the hardened steel of the punch tips. Not to mention the case is much softer, so if the drill bit slips off the punch, it’ll just eat the case.

After another day or two trying to make any progress, I just flip the transmission off and leave the garage.

Fuck it, I’m just going to throw Humpty’s transmission in so I can drive it around. Bad gear and all.